In the context of rising fuel prices, increasing operating expenses, and higher maintenance costs, choosing the right type of tire is not only a technical decision but also a strategic economic consideration for transport companies. The Comparison Between New DRC Tire and DRC Retread Tires has therefore become a key topic for many fleet operators weighing two popular options new tires and DRC retread tires each offering its own advantages and limitations.

This comparison provides a clear understanding of the nature, manufacturing processes, and real-world performance of both products. Through a detailed and structured analysis, we can evaluate new DRC tires and DRC retread tires to determine the most optimal solution for fleet operations.

1. Overview of New Tires and Retread Tires – Construction, Process, and DRC Technology

1.1. New DRC Tires – A Fully Manufactured Product Using Premium Raw Rubber

New DRC tires are produced entirely from natural rubber combined with high-quality synthetic rubber. The manufacturing process includes compounding, extrusion, building, curing, X-ray inspection, and strict physical testing.

Key advantages:

- High durability

- Stable traction

- Excellent load and heat resistance

- Minimal deformation during continuous operation

Applications:

Ideal for heavy-duty trucks, container trucks, and specialized vehicles operating continuously on long-distance routes or harsh terrains.

1.2. DRC Retread Tires – A Cost-Effective Solution Reusing High-Quality Casings

Retread tires are produced by reusing qualified tire casings and applying a new tread layer through modern extrusion and curing technologies.

DRC currently applies both cold-retread and hot-retread technologies, ensuring the new tread bonds firmly with the casing—achieving performance close to that of a new tire.

Key advantages:

- 30–50% lower cost compared to new tires

- Reliable durability across multiple use cycles

Applications:

Suitable for short-distance transport, construction trucks, or businesses aiming to optimize operating costs.

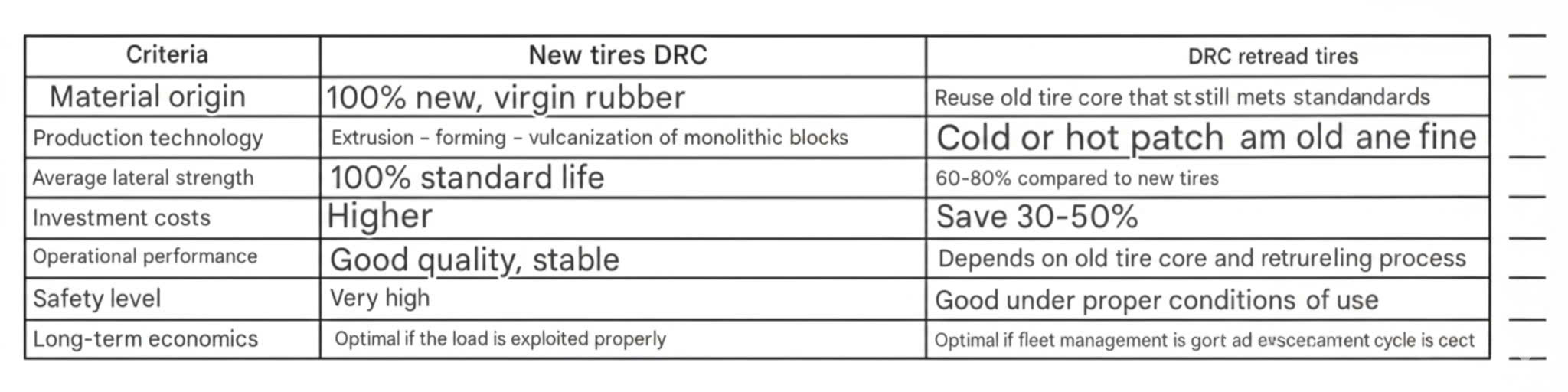

2. Comparison Between New DRC Tires and DRC Retread Tires – Technical and Economic Perspectives

Overall, the comparison shows that each type suits different operating conditions. New tires offer comprehensive performance, while retread tires are a smart option for long-term cost optimization.

3. DRC Retread Tires – A Cost-Efficient Solution Without Compromising Safety

Many operators hesitate to use retread tires due to concerns that “recycled products are not durable.” However, this perception is not entirely accurate.

DRC uses a strict casing inspection process, ensuring only casings that meet standards for elasticity, structural integrity, and uniformity are reused.

In addition, DRC’s hot-retread technology is performed inside controlled curing chambers with specific pressure and temperature settings, providing:

- Tread bonding strength reaching 90–95% of new tires

- Enhanced resistance to cracking and delamination on long routes

- Improved dynamic balance for smooth and stable driving

Therefore, DRC retread tires are not simply a “cheaper option,” but a smarter and more economical choice under appropriate operating conditions.

4. When Should You Choose New Tires and When Should You Choose Retread Tires?

4.1. Choose New DRC Tires When:

- Trucks frequently operate with full or heavy loads, or on long-distance routes

- High durability and stability are required, minimizing the risk of mid-route breakdowns

- Maintaining a professional brand image is important, especially for long-haul transport companies

4.2. Choose DRC Retread Tires When:

- Trucks operate on short routes (intra-province transport, construction sites, material hauling)

- You want to reuse high-quality DRC casings and save 30–40% cost compared to buying new

- The fleet has a proper maintenance schedule (pressure checks, load control, tire balancing, etc.)

5. Key Factors to Evaluate When Choosing DRC Retread Tires

To ensure safety and maximize performance, consider the following when selecting retread tires:

- Casing origin: Use genuine DRC casings or casings with equivalent certified quality

- Retread technology:

- Hot retreading for heavy-duty trucks

- Cold retreading for mid-sized trucks

- Service facility: DRC operates a dedicated Retreading Unit with ISO/PIANC certifications, producing reliable and high-quality products

- Post-retread inspection: Ensure the tread surface is smooth, without edge lifting or waviness, and that dynamic balance is stable

- Regular maintenance: Maintain proper pressure, rotate tires periodically, and check bolts and bearings frequently

In today’s highly competitive transport industry, selecting the correct type of tire is the first step toward controlling costs and ensuring optimal fleet performance.

- New DRC tires deliver maximum durability, safety, and overall performance.

- DRC retread tires provide significant cost savings, environmental benefits, and high technical reliability.

Understanding and comparing new and retread DRC tires enables fleet managers to make informed decisions aligned with operational goals, safety standards, and long-term profitability.

Read more: What Is Tire Pressure and How Does It Affect Tire Lifespan and Fuel Consumption