In transportation operations, truck tires are not merely the only component in direct contact with the road surface – they are a critical factor influencing fuel efficiency, safety, and vehicle durability. Therefore, mastering the guide to selecting truck tires not only helps transport businesses optimize operating costs but also ensures long-term vehicle performance.

1. Why is choosing the right truck tires important?

Truck tires carry heavy loads, operate on various terrains, and must ensure three key elements: durability – traction – fuel efficiency.

If the wrong tires are selected, it can lead to:

- Uneven wear or rapid deterioration → higher replacement costs

- Reduced stability at high speeds or sharp cornering

- Increased rolling resistance → higher fuel consumption

- Weakened braking capability → higher safety risks

Thus, understanding technical specifications, road conditions, and vehicle load characteristics is the first foundation when applying any guide to selecting truck tires.

2. Choose the correct tire size and specifications

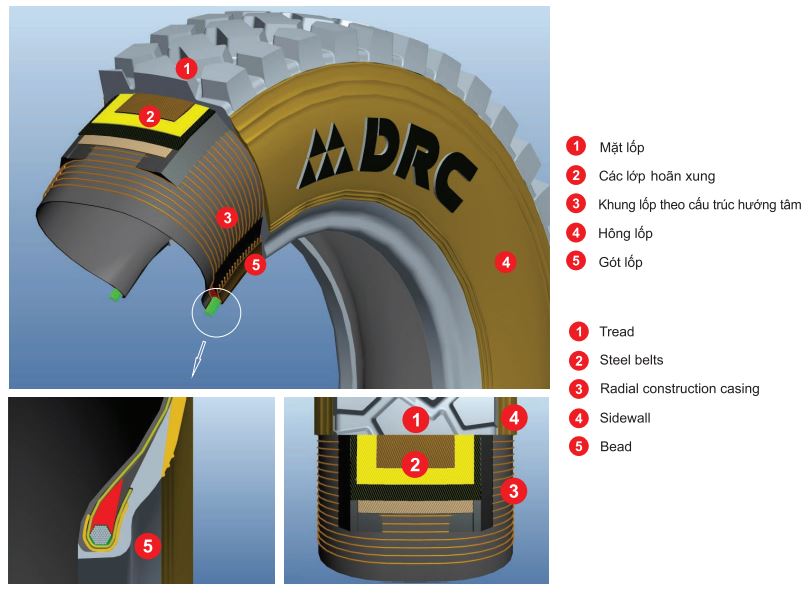

Tire sidewalls display codes such as: 11R22.5, 295/80R22.5, etc. Each part has its own meaning:

- Tire width (mm) – e.g., “295” = 295 mm

- Aspect ratio (sidewall height/width) – e.g., “80” = 80% of the width

- R – Radial construction (steel-belted), the most common technology today

- Rim diameter (inch) – e.g., “22.5”

When following the guide to selecting truck tires, the first rule is to comply with the size recommended by the vehicle manufacturer. Changing tire size may affect torque, wheel rotation speed, and even speedometer accuracy.

3. Select tires according to wheel position

Each wheel position on a truck experiences different loading and driving characteristics—requiring suitable tread and construction:

| Tire Position | Characteristics |

| Steer tires (front) | Require high traction and precise handling |

| Drive tires (rear) | Handle large loads, require strong pulling force |

| Trailer tires | Operate under heavy loads, long-distance movement |

Correct tread application can improve driving smoothness, promote even wear, and save 5–8% fuel compared to incorrect configuration.

4. Select tires based on operating terrain

There is no “one-fits-all” tire type. The guide to selecting truck tires must consider actual road environments:

| Road Type | Operating Features |

| Highways, paved asphalt | Smooth surface, few obstacles |

| Mixed surfaces (asphalt – concrete – gravel) | Medium traction, prone to wear |

| Construction sites, mountain passes, rocky roads | High loads, sharp objects, skid-prone |

Using improper tires may cause cuts, chipping, or separation due to excessive abrasion—especially in construction environments.

5. Consider load capacity and tire pressure

One of the most important elements:

- Do not exceed rated load: e.g., Load index 152/148 = 3,550 kg for single tire / 3,150 kg for dual

- Maintain proper pressure:

- Under-inflation → increased friction → overheating → blowout risk

- Over-inflation → center wear, reduced road grip

6. Choose reputable brands with strong after-sales support

A tire’s value lies not only in its structure but also in supporting services.

Reputable brands ensure:

- Genuine product origin, avoiding counterfeit goods

- Clear warranty policies (DRC offers 60-month warranty from manufacturing date)

- Technical support for wear inspection, pressure checks, and rotation service

With over 50 years of manufacturing truck and radial tires, DRC is a trusted choice in Vietnam and international markets — delivering durable and fuel-efficient tire solutions.

7. Economic efficiency: Quality tires reduce long-term costs

Choosing cheap tires to “save upfront” is a common mistake.

Actual statistics from DRC and large transport operators show:

- Tire costs account for 15–20% of total fleet operating costs

- Low-quality tires increase Cost per Kilometer by 20–30%

Proper tire selection + correct maintenance helps:

- Extend tire life 25–30%

- Reduce fuel consumption 5–10%

- Lower risk of unexpected tire failure

8. Technical tips when replacing or rotating truck tires

DRC experts recommend:

- Rotate tires every 20,000 – 25,000 km

- Check tread depth — replace when below 2 mm

- Perform dynamic balancing to prevent vibration and uneven wear

- Use genuine valves — prevent air leakage and rapid wear

- Do not mix old and new tires on the same axle — may cause pulling and abnormal wear

9. Expert advice from DRC: Choose the right tires — Invest in the right place

Truck tires are a long-term investment, affecting both safety and operational reputation.

A properly selected and maintained DRC tire can run 150,000 – 200,000 km while maintaining high stability.

Instead of “choosing cheap,” businesses should choose right:

✔ Right load

✔ Right terrain

✔ Right brand

Applying the guide to selecting truck tires properly helps transport businesses:

- Optimize fuel costs

- Reduce technical risks

- Extend vehicle service life

For over 50 years, DRC proudly stands with transport companies across all routes in Vietnam — providing high-quality truck tires suitable for every road and load condition.

Read more: Top 5 Best-Selling DRC Tires with Superior Durability